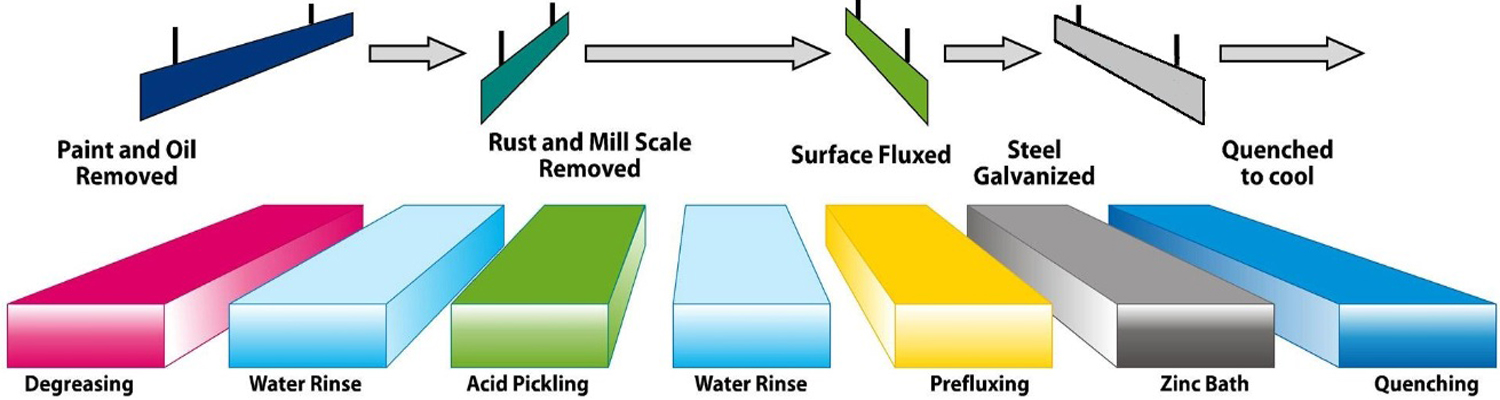

Berikut ini adalah beberapa petunjuk design produk yang direkomendasikan bagi fabrikator agar produknya dapat digalvanis dengan sempurna. Petunjuk yang lebih lengkap mengenai design yang direkomendasikan untuk hot dip galvanis dapat diperoleh di standar BS EN ISO 14713 dan publikasi-publikasi dari Asosiasi Galvanis.

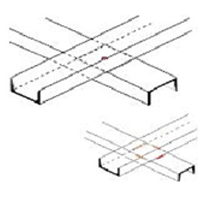

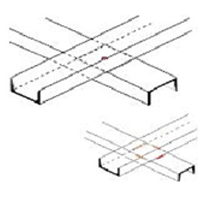

Overlapping or contacting surfaces are potentially dangerous as pretreatment solutions trapped between surfaces is converted to superheated steam in the galvanizing bath and can lead to an explosion.

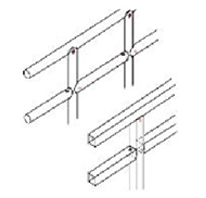

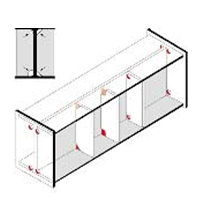

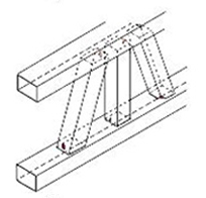

Every sealed section of a fabrication must be vented for reasons of safety and to allow access and drainage of molten zinc. Holes diagonally opposite each other should be as close as possible to the sealed end.

On structural hollow sections, provision must be made for venting and draining. With vertical members, drilled holes or V notches should be provided diagonally opposite each other at top and bottom.

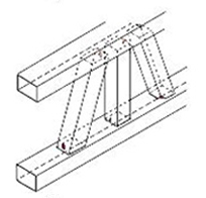

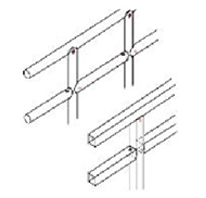

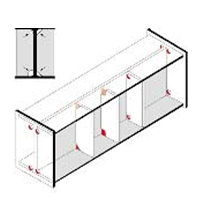

Angle bracings should, if possible, be stopped short of the main boom flange. This will allow the free flow of molten zinc across the surface of the flange, enhancing drainage from the structure.

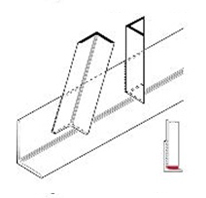

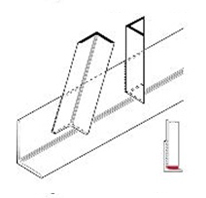

Cropping the corners of these brackets will aid access and drainage of molten zinc and a cleaner coating will be obtained.

External stiffeners, welded gussets and webs on columns and beams, and gussets in channel sections should have their corners cropped.